About Critical Chain Project Management

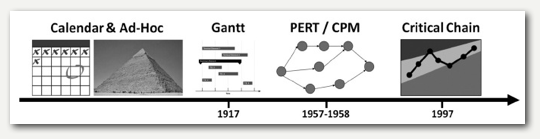

Project management, the systematic way of planning and managing time and resources to achieve unique, finite goals, probably has existed in one form or another for at least 5,000 years. After all, the Egyptian pyramids and other great ancient structures did not just build themselves—they were carefully planned and managed. Ad hoc and calendar-based planning methods have been used throughout history, but it was not until 1917 that an easy-to-understand display, visually organizing tasks and time, was brought into the modern workplace—Henry L. Gantt’s chart, now called the Gantt chart. Gantt charts were used in a multitude of projects, such as construction of the Hoover Dam (1931–1936) and the Manhattan Project (1942–1945).

The toolset of project management expanded when the critical-path method (CPM) was developed by DuPont in 1957 and the program evaluation and review technique (PERT) was developed by the Special Project Office of the Department of the Navy and Booz Allen Hamilton in 1958. Using CPM and PERT brought improvements over Gantt charts in the ability to manage projects with large numbers of tasks, interdependent tasks, and tasks with uncertain completion times. These methods were used to send people to the moon in the Apollo Program (1961–1972), as well as countless other projects since their advent.

As powerful as these tools have been, critical chain, a project management strategy and philosophy, represents the next major step in the progression of project management. Building on earlier advancements, critical chain cultivates the enhanced visual management and node networking aspects of its predecessors as well as incorporating new capabilities.

Identification and scheduling of project activities allow proactive management of variability. Critical chain project management can be of enormous utility in ensuring that healthcare projects are completed on time, within budget, and delivering all promised objectives. Instead of managing projects so that each task is completed on schedule, critical chain project management principles help to determine where to focus so that the entire project is done on time.

By strategically scheduling tasks and resources, critical chain positions buffers at key points to absorb the effects of unpredictable delays. By alerting relevant parties when projects begin to become delayed or when upcoming work will become crucial to the timely completion of projects, intervention can be well timed so that scarce management attention becomes focused where it will be most beneficial to the system. Well-managed buffers can help not only to adapt to the normal variation that exists in projects but also to serve to highlight special causes of delays when they occur.

LEARN HOW CRITICAL CHAIN WORKS BY "CHANGING THE RULES."

DOWNLOAD WHITE PAPER NOW >>

Many organizations operate in multi-project environments. Here, pipelining projects, or the strategic staggering of projects, becomes vital to resolving conflicts caused by contention for shared resources and makes adept use of a system’s constraints. To manage projects in this environment, critical chain project management software (such as Being Management 3 or Stottler Henke's Aurora-CCPM), is required to effectively capture all the benefits of using this methodology. Other project management software based on the critical path method are not adequately designed to operate and report effectively using critical chain project management.

DETERMINE IF CRITICAL CHAIN SOFTWARE IS RIGHT FOR YOUR BUSINESS >>

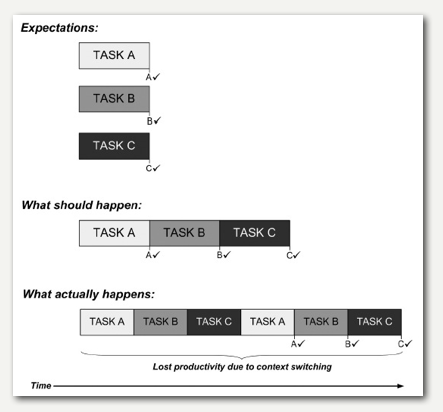

And unlike conventional project management methods, critical chain combats many of the behavioral tendencies people have that delay projects, such as bad multitasking, the unplanned switching between unrelated activities. Multitasking is not unique to any single industry; in today’s fast-paced business culture, most multitasking is regarded positively and even encouraged. However, suspending work on one task in order to work on another, unrelated task necessarily will delay completion of the suspended task. In such instances, multitasking becomes a source of great inefficiency and delay. This phenomenon is illustrated below and depicts the juggling of three tasks, A, B, and C.

By switching among tasks A, B, and C, each task finishes later than it would if the tasks had been done in sequence. The figure approximates the reality of the problem because delays caused by people forced to reorient themselves on their return to work on dormant tasks are taken into account. Moreover, when this switching delay occurs on certain critical tasks, the timely completion of entire projects can be compromised.

Critical chain project management even provides a way to counteract the safety time people add to inflate their time estimates to ensure that they will be able to complete their assignments by their due dates. Promoting high work visibility and clear status tracking, critical chain methods foster team trust and a "relay-runner" work ethic, which allows projects to be completed with the same resources at a much faster rate—20 to 50 percent faster or more in many established implementations. All that are needed for critical chain’s implementation are commitment from management, honest communications, strategic planning, and buffer management. Tools and technology can help people in prioritizing and scheduling their time to act in accordance with the success of projects and, ultimately, the organization’s objectives.

DISCOVER HOW CRITICAL CHAIN IS IMPLEMENTED.

DOWNLOAD OUR WHITE PAPER TO LEARN MORE >>

Project management success stories using critical chain have been reported widely in varying industries by such companies as Boeing, Hewlett-Packard, and others. After having used it in 2,523 public works projects in 2007 and over 4,000 public works projects in 2008, the Japanese government has recommended that critical chain project management “be used on all projects henceforth (approximately 20,000 projects per year).” The widespread use of critical chain resulted in average project durations cut by 20 to 30 percent or more, with some companies able to complete twice as many projects in the same timeframe with the same resources.

It is well known that software development and other IT projects are in high demand throughout the healthcare industry as treatments become more complex and medical records become electronic. After Eli Lilly & Co. applied critical chain to manage its IT projects, it began a pilot program in its pharmaceutical laboratories that concluded with “stupendous” results. Consequently, the Fortune 500 pharmaceutical company decided to use critical chain to manage every single product it has under development—approximately 190 projects, some that are six years long with 4,000 to 5,000 tasks. Its managers believe that “project management . . . is critical to the success of the complex, multiyear drug development process,” and critical chain will give the organization a distinct competitive advantage.

Eli Lilly became convinced of the power of critical chain when its success rate in reaching project milestones on time improved to 100 percent from its 60 percent past average. John C. Lechleiter, CEO of Eli Lilly, described a pivotal point in the company’s history when it entrusted its launch of a center of excellence to “streamline the development of new medicines with one common operating system, one common set of priorities, and a singular focus.” Critical chain project management was credited not only as a pillar of the center of excellence but also with transforming Eli Lilly’s relationships with clinical research organizations and other external providers.

Follow Us: